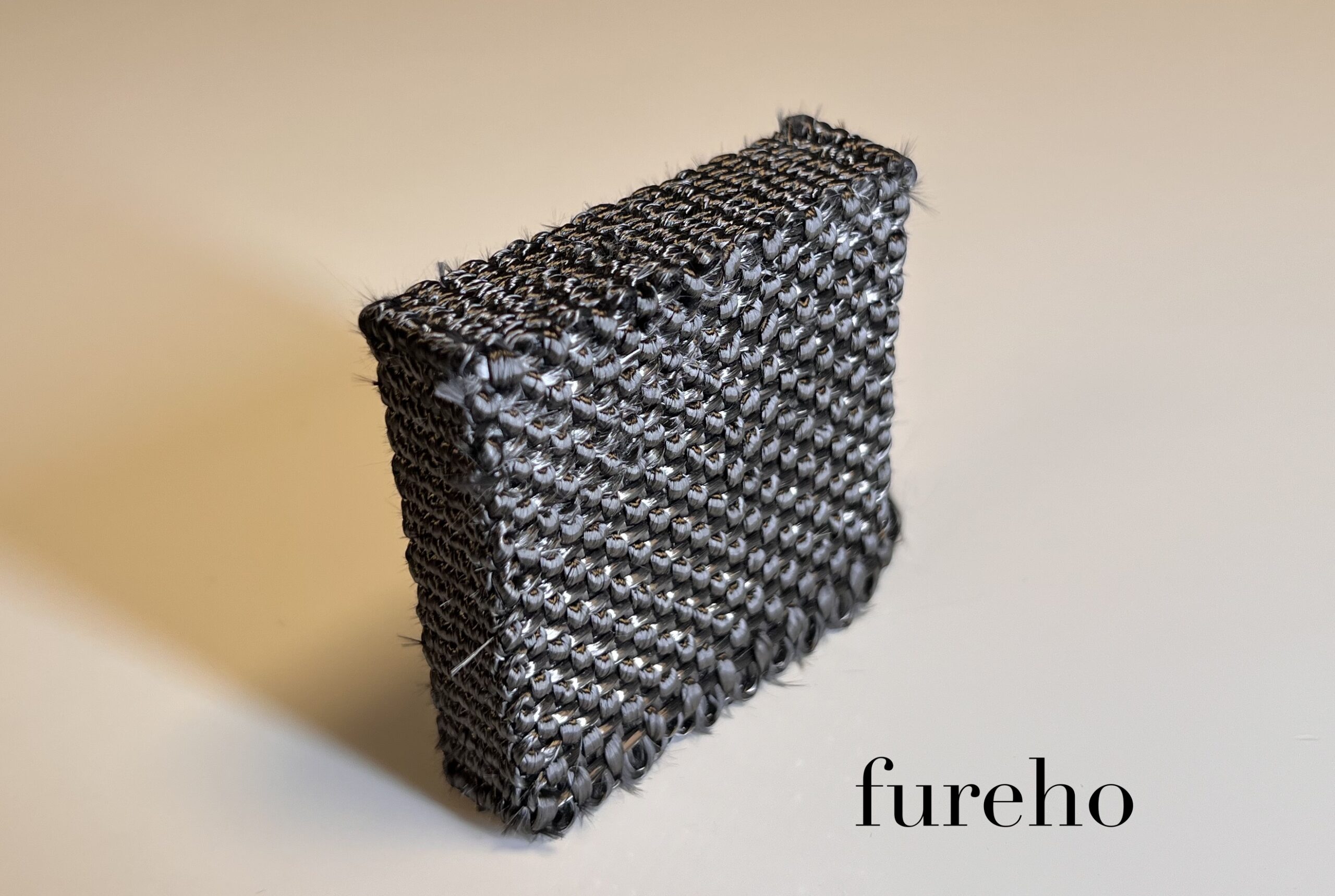

Fureho is an advanced materials deep-tech start-up, incubated at the European Space Agency’s Business Incubation Centre in Sweden. We pioneer near net-shape Noobed 3D fabric reinforcements for unlocking new possibilities for next-generation ceramic and polymer matrix composite materials using our proprietary Noobing Technology Platform. This technology enables the engineering and production of near-net shape 3D fabric pre-forms with load-aligned fibres in X, Y, and Z (through-thickness) directions. For SPACER, this capability is directly applied to engineer electrode structures with through-thickness direction fibres for improved fluid dynamics and electrical and thermal conductivity, which is essential for high-performance Redox Flow Batteries.

Main tasks in SPACER

Fureho is responsible for developing a Thermal Model for Porous Electrodes, specifically focusing on heat and mass transport coupled with the Lattice-Boltzmann approach. Our expertise will be leveraged to develop and test Noobed 3D fabric pre-form electrodes of carbon fibres with directional fibre alignment via the Noobing technology. This work aims to define and validate the optimal fibre alignment to support both fluidic and heat transport in the electrodes.

»Fureho is participating in the SPACER project to contribute its expertise in engineered Noobed 3D fabric pre-forms to design and validate optimal load-aligned fibre architectures for porous electrodes, directly supporting higher power density and efficiency in Redox Flow Batteries.«

Prarthanaa Khokar